My new Observatory Build

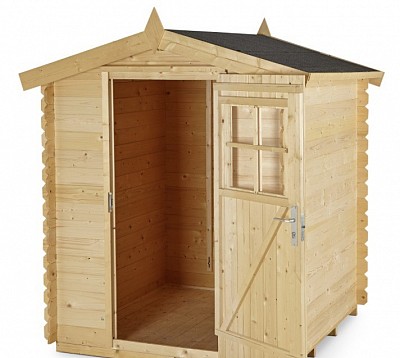

Shed for Conversion

So I have decided to build an observatory around my existing steel pier, this will be purely to house the mount and scopes and have enough room to mover around in, if needed, my conservatory is only a couple of meters away so no need for a warm room. I decided on a shed conversion, the one shown on the left, it’s a sold construction of 20mm solid wood, and more importantly it comes with a solid door with good lock and hinges. It’s 5 foot square internally, which will be fine for my needs, and I found it reduced on the B&Q website from £570 down to just £300...perfect. The next thing was deciding on a roll off roof design or an open out in two halves design, and I have settled for the later.

And so the build begins....

Ok, so the shed arrived and I soon got it all unpacked, to check and make sure all pieces were present and correct. Happily they were all there so the build began. I marked out the area, but knew it could be moved when needed as the frame was not massively heavy at this point...and final adjustments on position would be needed.

Next came the fitting of the nice solid, already assembled door, with good lock and a vandal proof Perspex window, (which I did not want). The frame was in three parts, two sides and the top, the sides were “U” shaped and just slotted onto the panels, and the top pieces screwed to the top of the uprights. I fitted the two 3” hinged and proceeded to hang the door. All good, so I proceeded with the lock. this was the last job on this first day of the build.

Start of day three of the build. Once the supports were fitted now it was time to remove the roof panels, cut them to final size on the widths, and the length at the apex end...and fit the EDPM rubber membrane. The shed came with a roll of felt, but decided on EDPM as it was a bit lighter in weight. looked better when fitted and would last over 50 years, apparently... This was not easy to fit, I had never used it before and it was a learning curve, getting the rubber on at the correct time and making the corners look nice and neat, I stapled it under all the edges and fitted the drip trims on all three sides (not the apex side) and then fitted the hinges and support beam to the roof panel and hauled it up on the shed and secured the support beam back in place.

So the end of day three of the build and all fitted and watertight, I was very happy with how the roof had worked out and it had fit perfectly as I had imagined, just need some bad weather now to test. The panels were a bit heavier than expected, but still fine for a big bloke like me to man handle.